Freight Claims Do’s & Don’ts

Having damaged freight can cause anyone to get frustrated. Filing a freight claim can even be more frustrating to someone who is not familiar with the process. There is a lot that goes into the freight claims process and it is important to know that damaged freight isn’t the only type of freight claim you may encounter. We will go over what freight claims are, how to properly file a freight claim and the do’s and don’ts when it comes to the freight claims process.

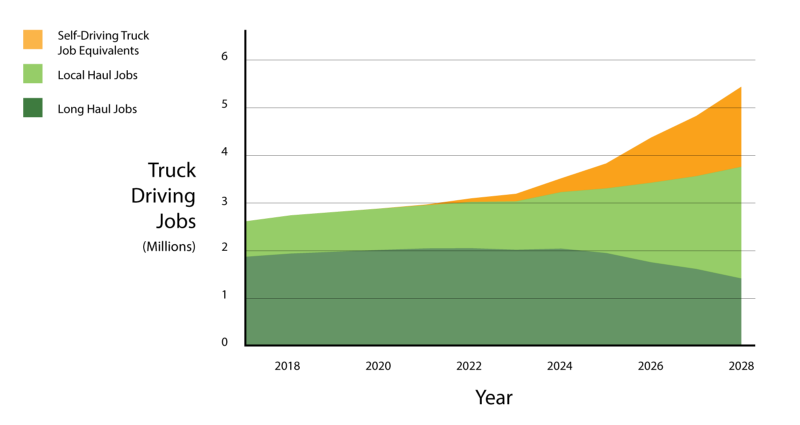

Truckers, Self-Driving Trucks Aren’t That Bad

Self-driving trucks have been the topic of the year for 2018 so far. With last year’s announcement of the Tesla Truck, it has only grown in hype. Uber and Tesla have been front running the autonomous market for some time and are in competition to have the first truck on the market. But there are other companies around the world as well in regions such as Asia and Europe. The concept of a self-driving truck has been around for years, so why all the commotion about it now?

PLS Logistics Strengthens Partnership With The Independent Steel Alliance

CRANBERRY TWP., PA (March 20, 2018) — PLS Logistics Services, one of the largest industrial 3PL transportation service provider in North America, has partnered with the Independent Steel Alliance to sponsor their Annual Shareholders Meeting in Napa Valley, CA, in April.

New ELD Waiver For Agriculture Carriers

We are two weeks away from one of the most discussed dates in the transportation industry this year. Carriers were given a grace period between December 18 and April 1 to ensure ELD compliance. The soft launch was intended to facilitate the transition. Despite the push-back from carriers and attempts to overturn the new regulation, FMCSA will begin full enforcement of the ELD compliance on April 1.

The 14-Hour Driving Window Dilemma

The FMCSA issued hours of service (HOS) regulations for truck drivers that limit the maximum time that can be driven in a period. Recently in the transportation industry, the OODIA made a petition to the FMCSA to create more flexibility for drivers so that traffic, weather or dock delays don’t impact their drive time availability. They are requesting that drivers who fall under the HOS regulations are given a rest break (up to three hours) once for every 14-hour duty. This rest break would be to stop the continuous 14-hour window drivers are given to operate. However, this would not eliminate the consecutive 10-hour off-duty break that is required before each shift.

What Are Chameleon Carriers?

Most shippers and 3PL’s are practicing quite strict and thorough carrier vetting procedures nowadays. This is an absolute must in today’s freight world – implementing and following thorough processes for carrier screening is the only way to ensure you’re dispatching your or your customer’s freight into good hands.

Women Who Shaped The Trucking Industry

This year, Women’s History Month is observed in March. This month is dedicated to celebrating accomplishments of all women in all aspects of our lives. Today, it’s hard to imagine the trucking and logistics industry without women. In today’s , we want to tell you a little bit about the history of women in trucking, who they were and how they fought for women’s rights in a profession viewed as predominantly male.

Trending Transportation Updates: February 2018

UPS Bought Electric Vehicles to Increase Sustainability

Sustainability is a hot topic today that is pushing many companies to “go green” and adopt new technology that is environmentally friendly. UPS has taken a step towards being more sustainable by purchasing 50 electric vehicles. Electric vehicles can save companies lots of money by reducing the cost of maintenance along with fuel costs. UPS acquiring these electric vehicles puts them ahead of other companies who may be looking to do the same and acquire electric vehicles themselves to stay ahead of technology advancements being made in the industry. To read more, click here.

LTL Shipping Made Easy: What Should You Know

Less-than-truckload (LTL) is often our go-to for smaller shipments. It is more structured and often more cost-effective than simply shipping your freight as a partial load, not to mention that it’s much easier to arrange.