Snow Piles on Trucking Delays

Winter weather is a real concern for transportation in 2015. The devastation caused by snowstorms impacts everyone, including truckers, state officials, shippers, and others.

PLS Logistics Services Continues to Grow, Opening Office in Philadelphia

New office to bring 150 new jobs to Philadelphia

Supply Chain Visibility

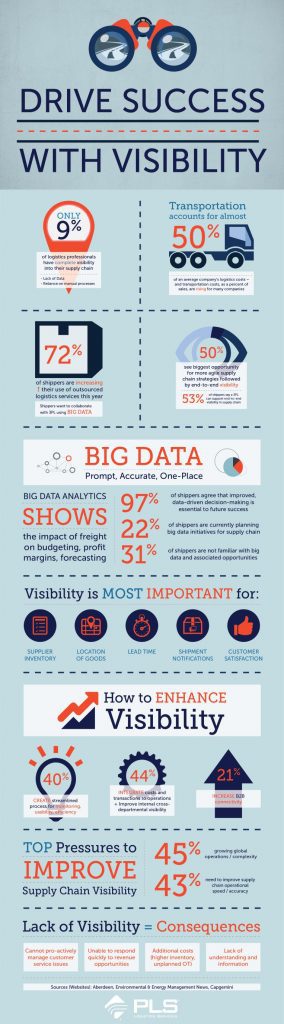

Visibility into the supply chain is a fundamental part of implementing improvements. Identifying inefficiencies is the first step to increase delivery speed, accuracy and reducing transportation costs. For many supply chains, growing global operations, big data and demanding customer expectations all strain logistics functions, making visibility more important than ever. Transportation costs continue to rise for most companies. Visibility presents a great opportunity for significant cost savings. Full visibility into the supply chain improves all business operations and can provide a competitive advantage.

How to Set Up a BYOD Policy

Smartphones and tablets are embedded in every aspect of our life; think about how personal devices can change – or, have already changed working environments and communication processes in companies. The hype over the BYOD (bring your own device) trend started years ago, yet it yields questions and predictions. Gartner forecasts that by 2017, half of the employers will require workers to supply their own device at work. Whether it’s good or bad for business, it’s happening – and logistics companies better be prepared for the changes.

Supply Chains Prepare for Valentine’s Day Demand

Love is in the air! Or, in the case of many suppliers and retailers, on a freight truck. That’s right, all of the thoughtful gifts that you receive this Valentine’s Day made their way to your home through a complex, well-planned supply chain. With seasonal demand, suppliers, carriers and retailers must work together to optimize logistics to make your Valentine’s Day special.

Discover Your Competitive Advantage

According to Capgemini’s 2014 study, 72% of shippers are increasing their outsourced logistic services this year and 78% of third-party logistics providers (3PLs) have declared an increase in outsourcing among their shippers. What are the main advantages of outsourcing and why does this trend continue to grow among all types and sizes of shippers? Let’s take a look at the central reasons for hiring a 3PL and the various levels of outsourcing that a shipper should consider.

Two Critical Ways To Determine LTL Shipping Rates

Since we’ve discussed shipping class rates in the about density-based pricing post, it is worth mentioning weight breaks and classification, an important part of freight pricing. When it comes to finding the best rate for a company’s shipping needs, freight class and weight are two pricing factors that shippers should evaluate before making the final decision.

PLS Logistics Services Continues to Grow, Opening Office in St. Louis

New office to bring 150 new jobs to St. Louis CRANBERRY TOWNSHIP, PA – February 5, 2015 PLS Logistics Services (“PLS”), a leading provider of third-party logistics solutions and freight brokerage services, today announced that it has opened a new branch office in St. Louis. This is PLS’ seventh office nationwide, and was opened to meet the needs of PLS’ expanding regional client base.

Senator Sanders Introduces $1 Trillion Infrastructure Bill

On January 3rd, Senator Bernie Sanders (I – Vt.) announced he’s creating a bill that allows $1 trillion in spending over several years for infrastructure funding. This is much needed relief for the transportation industry as the Highway Trust Fund has been running on short-term fixes since 2008.

What to Know: Density Priced Shipping

In order to understand density priced shipping, start by understanding traditional freight rate classifications. These rates define how much a particular kind of load will cost, as defined by National Motor Freight Traffic Association (NMFTA) and made available through the National Motor Freight Classification (NMFC). Products are classified by specific parameters: