June Transportation News Round Up

TransportatioNews

This month, there’s been many new developments and news stories affecting the transportation, logistics and supply chain industries. Here is a quick guide to 6 of the most talked about stories, check them out:

Infographic: Fireworks and Hazardous Materials

54_facebook_uploaded_image

Whatever your plans are for the 4th of July, you’ll inevitably run into some sort of fireworks display. Whether it’s a professional show or relatives shooting off some bottle rockets in the backyard, it’s important to remember that fireworks are hazardous materials. The following infographic explains why fireworks are considered hazardous materials and how to stay safe during Fourth of July celebrations.

What Can We Expect for the Rest of 2015?

WhatsAheadEarlier this year, we predicted what opportunities and trends would be most popular within the supply chain and transportation industry. Supply chains, no matter the industry or company size, must keep up with the latest developments and news affecting transportation, logistics and business partners. As technology springs forward, 3PLs and shippers find more collaboration – working toward innovative solutions for time and cost savings.

JSW Steel (USA) Inc. Announces Agreement with PLS Logistics Services

BAYTOWN, Texas, June 23, 2015 /PRNewswire/ — JSW Steel (USA) Inc. (“JSW”) has entered into an agreement with PLS Logistics Services (“PLS”), the largest industrial 3PL transportation services provider in North America. PLS will provide transportation and logistics solutions for outbound steel plate shipments from JSW’s plant in Baytown, Texas.

Is a Non-Asset Based 3PL Right for Your Company?

non-asset based 3PLThere are several benefits to your business when outsourcing the supply chain. As it will reduce costs, improve service and allow the shipper to focus on core competency. Third-party logistics firms give you a chance to provide value through solutions, service, and expansion. There are two categories of 3PLs: asset-based and non-asset based 3PL.

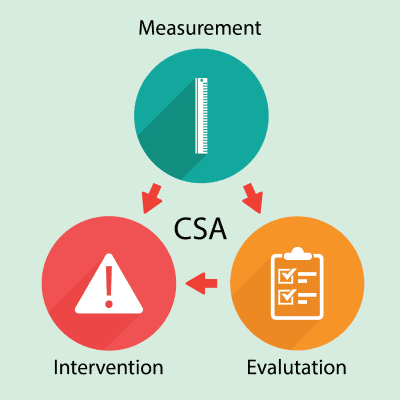

The Foolproof Guide to Understanding CSA

What is CSA? There are more than 500 million trucks and bus carriers in the US and the Federal Motor Carrier Safety Administration (FMCSA) does its best to execute safety regulations for all of them. In 2010, the FMCSA launched the Compliance, Safety, and Accountability (CSA) initiative to improve large truck and bus safety. The measure was intended to reduce crashes and injuries and better report safety problems.

5 Things Carriers Should Stop (Now)

Drivers and Carriers – Whether you’re a business owner, a freight forwarder or a 3PL company, your performance relies on the productivity and efficiency of trucking companies. Even if your own business processes and activities are perfectly adept, the supply chain still depends on how quickly and carefully trucks deliver freight from point A to point B.

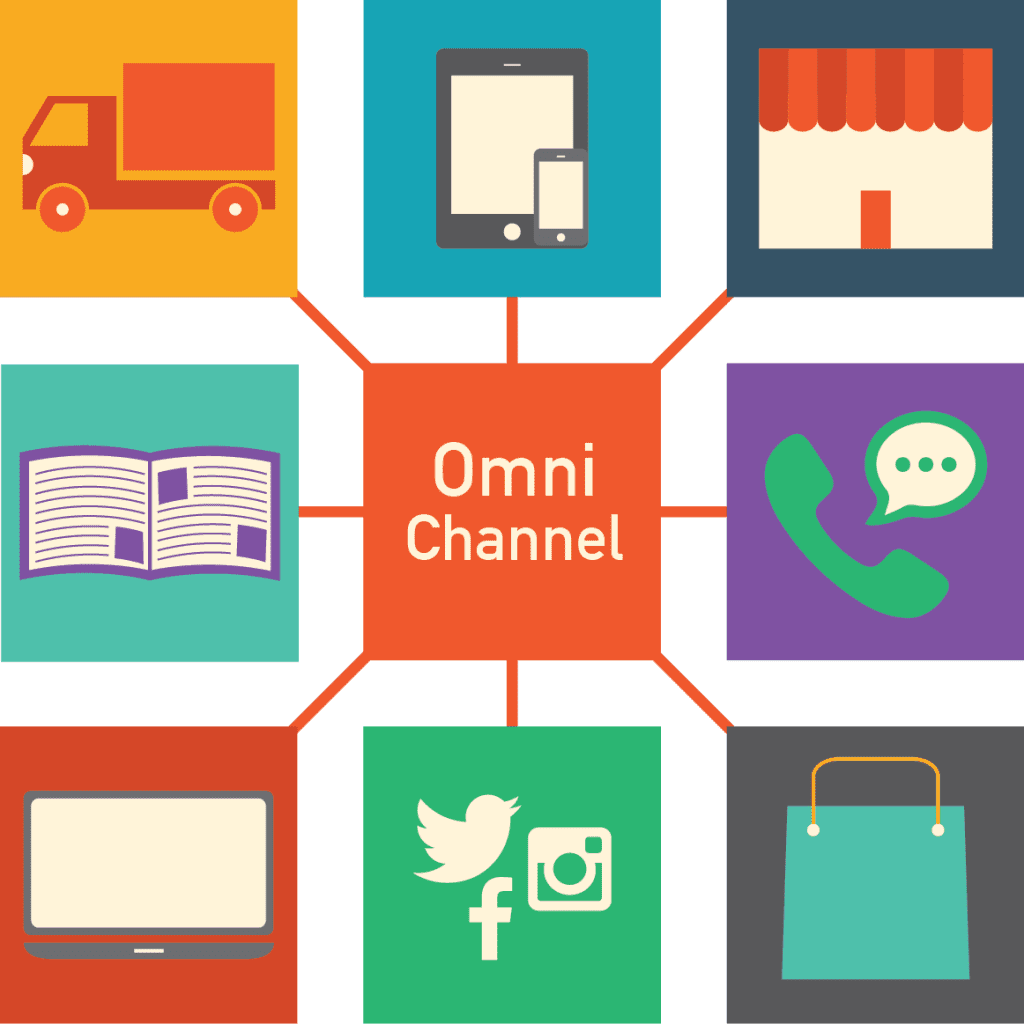

Quick Guide to Omnichannel Fulfillment

omnichannel fulfillmentWhat is omnichannel fulfillment?

The omnichannel fulfillment model developed because of the growing number of consumers who demand better shopping experiences, whenever, where ever, they want. According to a recent Pulse study, 44% of customers want the ability to buy online and pick-up at the store. 62% of customers want the ability to purchase online and make returns in-store.

The Difference Between Logistics Management and Supply Chain Management

Shippers often confuse the terms “logistics management” and “supply chain management”. Each word is used to describe very similar functions and operations in the transportation industry. However, there is a difference between these terms.

The Growing Truck Driver Shortage: A Critical Challenge for the US Trucking Industry

Carrier

There is an undeniable tightness in the trucking industry’s driver market. Trucking employed more than 7 million people in 2014, 3.4 million of those were drivers. But still, carriers feel the real impact of the unwavering driver shortage. Why is America having a difficult time retaining and attracting truck drivers? Mostly because of strict regulations, relatively low pay and a universal lack of interest in the career. Carriers are working hard to end the problem, changing how they recruit and retain drivers – increasing pay and hiring new driver’s right out of training programs.