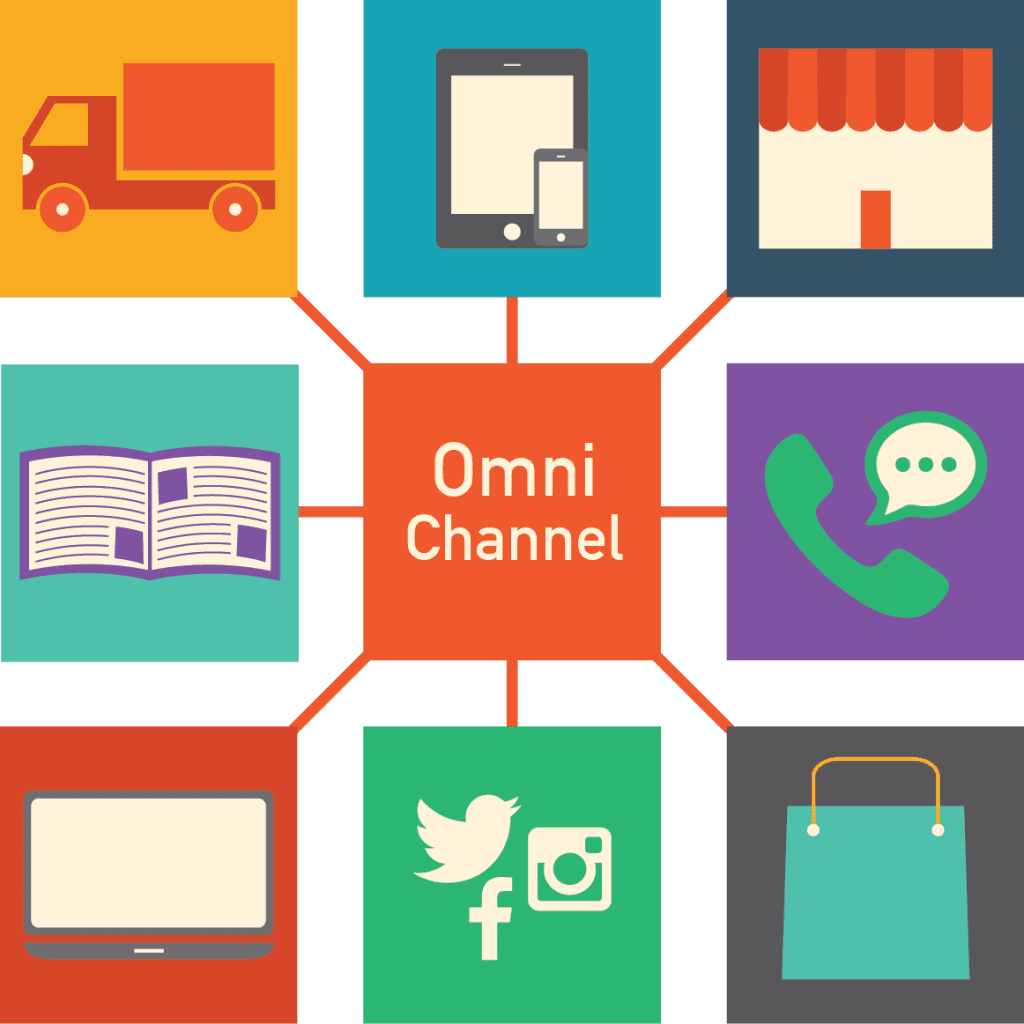

4 Keys to Improving Your Omni-Channel Strategy

Omni_Channel__GraphicRetailers are struggling to keep pace in the highly competitive omnichannel environment. Consumer desires for immediate delivery and personalized service are an ongoing challenge. Many shippers aren’t able to support a productive, efficient supply chain.

Inbound Freight Management Benefits | PLS Logistic Services

benefits of inbound freight managementWhat is inbound freight management?

Inbound freight management refers to monitoring and managing inbound shipments that come from suppliers or vendors. Transportation accounts for almost 50% of the average company’s logistics costs. Shippers can gain more control of these costs when they choose to make inbound freight management a supply chain priority. With inbound vendor management, attention is focused on shipment integrity, customer satisfaction and tracking information. Choosing to manage inbound freight gives shippers a chance to improve reliability, gain visibility and reduce costs.

April Transportation News Round Up

The top transportation news from April.

Effects of the Driver Shortage

The truckload driver shortage is becoming a serious financial concern for shippers. To attract new drivers, many carriers are improving training, retention and compensation packages. However, they continue to struggle to find the number of drivers necessary to keep up with demand. The driver shortage has a significant impact on the tight over the road capacity that is causing issues for shippers who now have to pay a higher rate to move their freight.

Reverse Logistics: Everything You Need to Know

What is the meaning and value of reverse logistics within the supply chain? Many people think of reverse logistics as handling customer returns and defective goods; that it is limited to customer service and recycling. However, only 25% of all goods in reverse logistics consist of defective items. It includes managing recalled products, overstocks, fixtures, recyclables, capital assets, end-of-life goods, and assets to be disposed.

Should Fuel Surcharges Cost Me This Much? Infographic

Fuel prices are constantly fluctuating. Do your fuel surcharges reflect this? Don’t know? This infographic will explain everything you need to know about fuel surcharges and how a 3PL can make sure you’re paying a fair price.

Top 4 Consumer Shipping Expectations

PeopleEscalatorConsumers have access to more information than ever before, and with various options for online ordering, paying and shipping, customer loyalty is low. Today’s omni-channel era means retailers and shippers must pay close attention to customers’ high expectations. A customer’s experience with a company is greatly impacted by shipping options. Consumers are known to revisit an e-commerce site if the supplier offers low prices, free shipping and/or fast shipping. Today, 86% of buyers will pay more for better customer service, according to a CEI Survey, but only 1% think retailers meet their expectations. So, what are these customer expectations?

6 Effects 3D Printing has on Supply Chains

You’ve heard about the fascinating achievements in 3D printing. Printers can now create customized apparel, personalized make-up and can even be used in medicine. As 3D printing becomes more integrated into manufacturing, it is easy to conclude that logistics should be influenced as well. Has the adjustment process already started?

PLS Logistics Services Hires Jon Herberger as Chief Information Officer

Mr. Herberger most recently served as Senior Vice President and Chief Information Officer at Imagitas, a marketing services company that connects marketers with their consumer segments through government communication channels in the US. Before joining Imagitas, he held senior technology management positions at N.E.W. Customer Service Companies Inc. and Electronic Data Systems.

PLS Logistics Services Continues Expansion, Opening Office in Phoenix

The office opened Monday April 6, 2015, with an initial team of 13 employees, 6 who were previously located at other successful PLS offices across the country, and 7 new hires from the Phoenix area. Located at 7001 North Scottsdale Road Scottsdale, Arizona the office is expected to create over 200 jobs in the greater Phoenix area over the next three years.